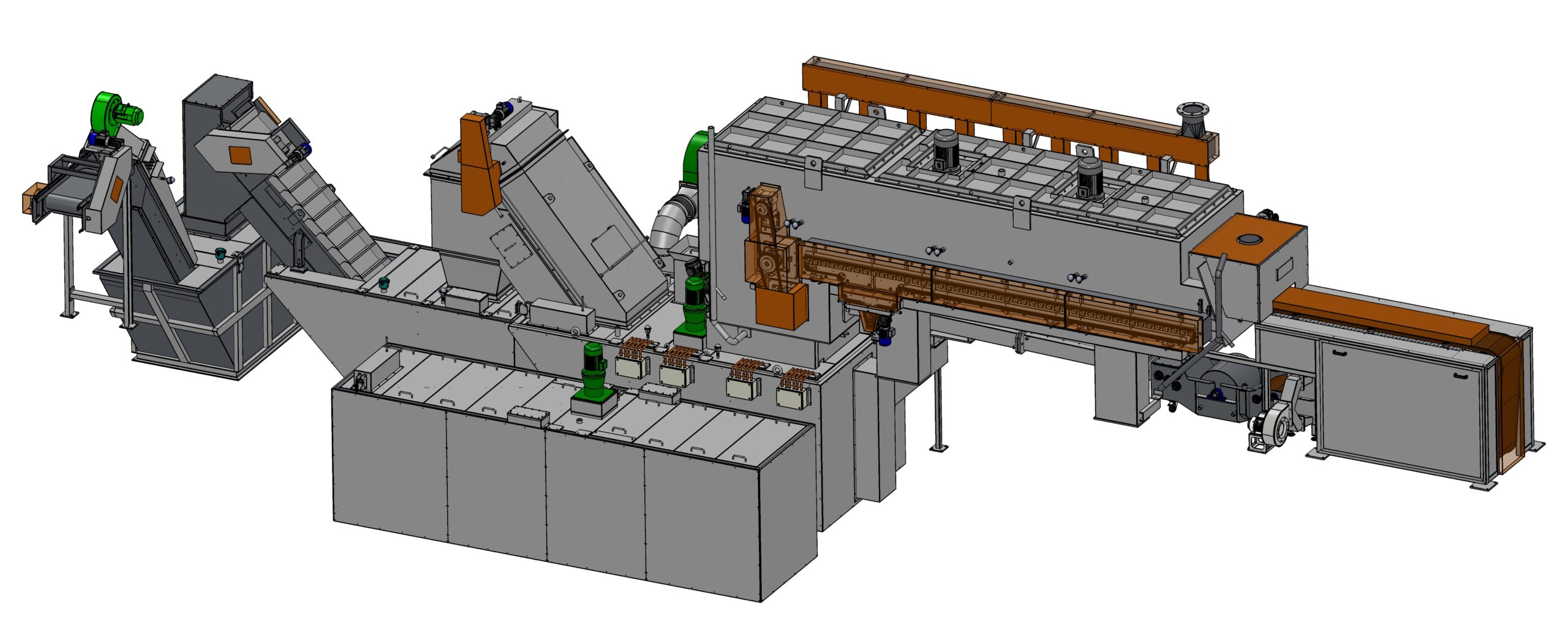

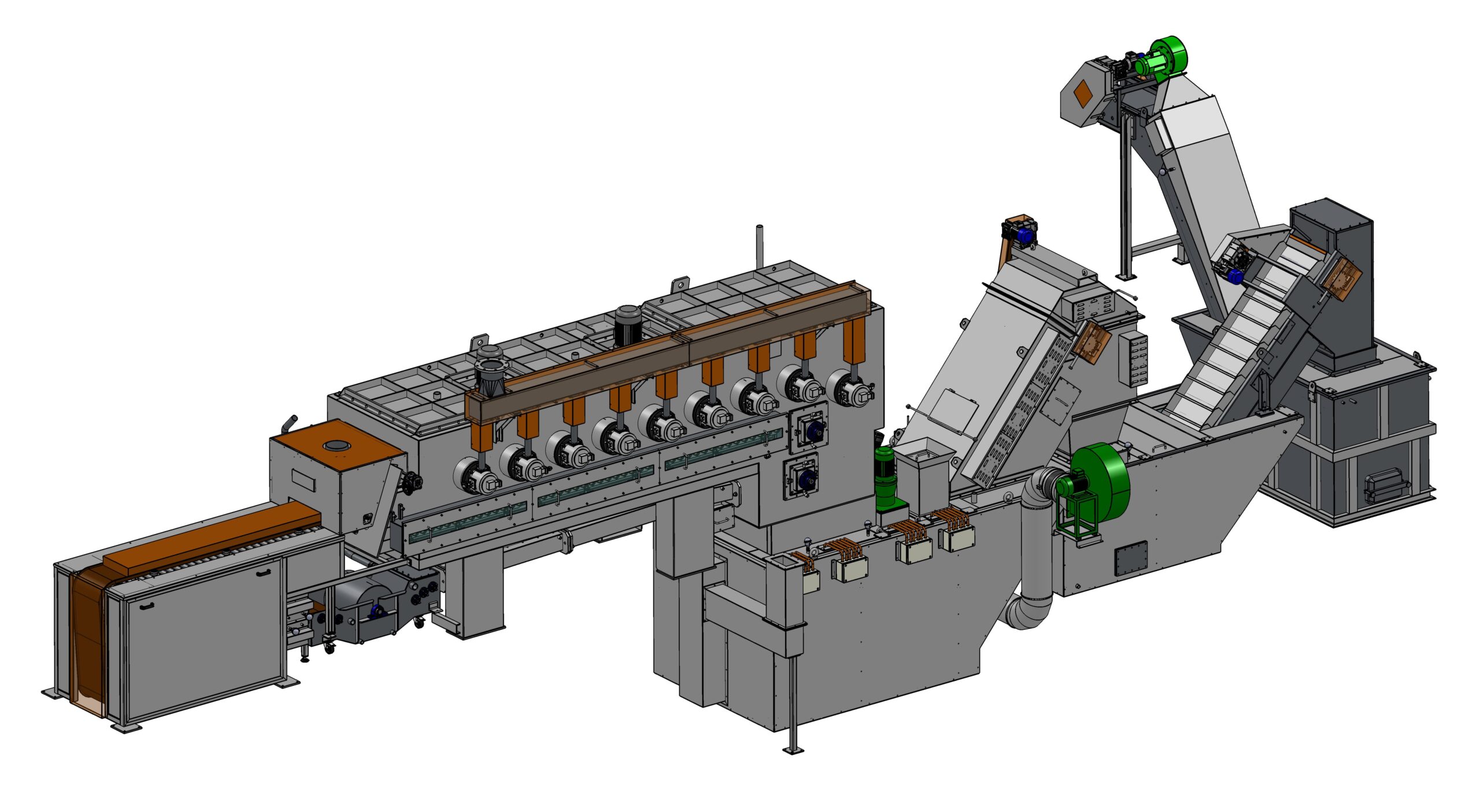

Sabe Forni produces bath furnaces with molten salts that are designed for highly specific uses according to the type of metal that has to be processed. The cooling process of pieces, that were previously heated with the austenitic treatment, takes place inside a liquid mixture of alkaline nitrite and nitrate heated to melting temperature. The complete and drastic hardening process is avoided, maintaining the pieces above the Ms level for the necessary period of time with the purpose of obtaining the structural balance and also, after a further slow cooling process, the martensite not only on the surface but also in the inner part of the pieces, otherwise this will impede the expansion of the interior mass (martempering). Later, the cooling process continues inside warm water, where the layer of salt on the surface of pieces melts.

If pieces remain longer inside warm water, austenite turns into bainite (austempering).

Long and thin pieces such as knives, screwdrivers, parts of weapons, springs, tools in general, are usually processed with thermal tempering even in continuous furnaces with controlled atmosphere for the heating and subsequent cooling process in molten salts. These plants are complemented by washing tanks with water and devices for the retrieval of dissolved salts. The tempering process in molten salts doesn’t require subsequent treatments, if the elements that have to be processed are made of appropriate steel with limited thickness.

Learn more about our plants of bath furnaces with molten salts and contact our experts.